We know laser processing like anyone else

Any custom-made shape

Components ready to assemble

Fast delivery time even for complex orders

What guides us? What is important to us?

At the heart of our facility are advanced technologies that enable us to optimize production processes and improve efficiency, flexibility and safety.

Our goal is to effectively support our customers’ competitiveness. To make this possible, we have introduced specialized software and systems leading to full automation. This approach allows us to plan production, minimize failures, ensure continuity of processes and improve the quality of products.

As a result, we can offer our customers a more flexible and efficient manufacturing process. The benefits of cost reduction and time-to-market allow you to gain a significant market advantage over your competitors.

Huge possibilities of modern technologies

Modern technology allows us to laser cut any shapes from sheet metal, profiles and sections in a very short time – faster than if we used other methods of processing. After laser cutting, the details are ready for assembly and usually do not require additional operations, such as drilling, marking or grinding.

We also produce heating devices and ventilators as well as hot air distribution systems.

We have completed many different projects – from single orders to thousands of serial orders.

PRODUCTION

Through the use of highly efficient machines, selection of tools and finished product control techniques, we optimise our manufacturing processes, thus achieving the lowest possible production costs while maintaining the highest quality of finished products.

DESIGNING AND PRECISION METALWORKING

We specialise in the production and implementation of services in the field of machining and electrical discharge machining, using CAD and CAM technologies, which shorten the time and reduce the costs of design and prototyping, while maintaining high accuracy and repeatability of details. We design parts, subassemblies and entire machines and devices, also based on our customers' concepts.

A FULL RANGE OF ASSEMBLY SERVICES

We carry out the assembly of units, subassemblies and finished products from components manufactured in our plant or automation and electronics modules delivered to us by the customer. We conduct both large production series and single orders. We support the entire process - from the design of elements, through production and testing, to storage or transport - all according to the individual needs of the customer.

Our standards

Quality

Modernity

Precision

Customer satisfaction

Quality control is an integral part of the production process. Our controllers verify products with material certificates, as well as assess the compliance and correctness of the elements at various stages of production. On a daily basis, we make sure that our services are kept at the highest level.

Find out more about our Quality Control

See what we can do for you

… and we can do a lot! For over 20 years we have been fulfilling orders for many customers and subcontractors from various industries. Not sure if our offer is for you? Contact us and we will gladly advise you!

Do you want to know more about our offer?

What equipment do we use?

Professional machinery helps us to carry out even the most demanding orders. Each device has slightly different parameters and purpose, and our employees decide on their selection, analyzing the needs of a given customer

Need more information or want to ask about an offer?

Laser cutting machines

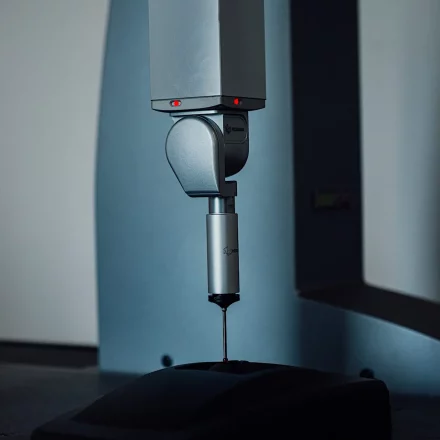

Modern Trumpf machines allow for laser cutting of metal sheets with an accuracy of 0.1 mm, the smallest details and any shapes.

Laser cutting machines for tubes and profiles

3D laser cutting machines enable non-contact processing of profiles and pipes of various cross-sections with automatic loading and unloading of material.

Bending brakes and eccentric presses

Thanks to advanced CNC control and automatic compensation of the deflection arrow, our presses allow for accurate and repeatable bending of metal sheets.

Waterjet cutting machines

Water jet cutting is an innovative method of processing any materials, even the demanding and hardened ones up to 200 mm thick.

Milling machines and machining centres

They are used for precision machining, including For the production of tools and moulds, medical equipment, parts of machines and devices, and automotive industry products.

Lathes and turning centres

They provide a wide range of precision machining for the most demanding details. CNC turning gives you the option of complete automation.

EDM machines

Charmilles die-cutting and wire EDM machines are high-class machines that allow the production of various tools, blanking dies and molds, and enable the processing of materials with increased hardness after the hardening process.

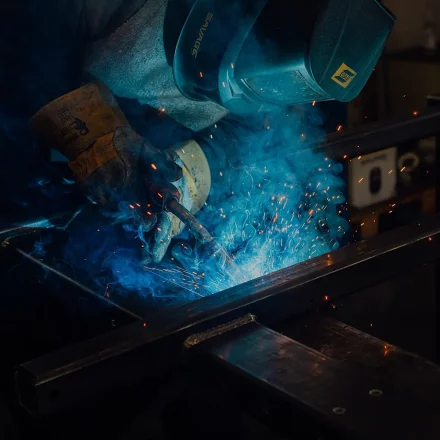

Welding stations

Our devices and welding cells, by using laser technologies and other TIG, MIG and MAG methods, allow us to weld repetitive and precise structures.

Punching machines

TruMatic machines offer the possibility of machining and perforating standard contours and molded details such as fasteners and threads. The production is carried out in a fully automatic mode of loading sheet metal and unloading finished details.

3D laser welding and cutting

Laser systems allow for the processing of 2 and 3-dimensional elements, both in terms of cutting and welding.

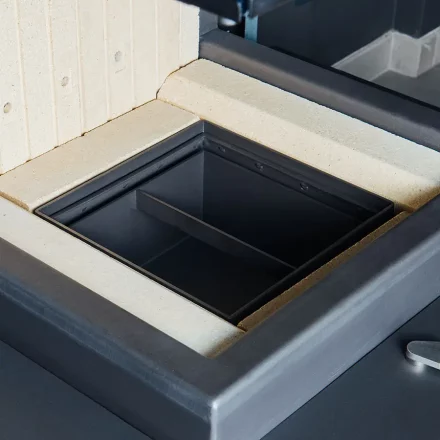

INTERFLAM

INTERFLAM DURO convection heating inserts are products with high aesthetics and the highest efficiency. The main advantage of convection inserts is the ability to quickly deliver a large amount of hot air. The convection system is a good solution for apartments with a large cubature and a significant heat demand.

QUALITY CONTROL

We are true experts in our field, so we demand a lot from ourselves and the products we create. Having a team of great specialists and a modern machine park, we can create projects that will pass the highest quality control – first our own (for which we use special control devices), and then also our customers.

Quality

Find out more about our standards

We have had many successes

over 20 years

on the market

over 500

completed projects

over 1000

satisfied customers

over one million

products sold

Do you need more information?

Our customers

The list of our customers includes both small and large enterprises with different business profiles - we currently permanently cooperate with approx. 400 companies.

Global reach

Our products are sold on the Polish and foreign market.

Flexible collaboration

We carry out one-off projects and large-scale orders, choosing the best cutting technology for each order.